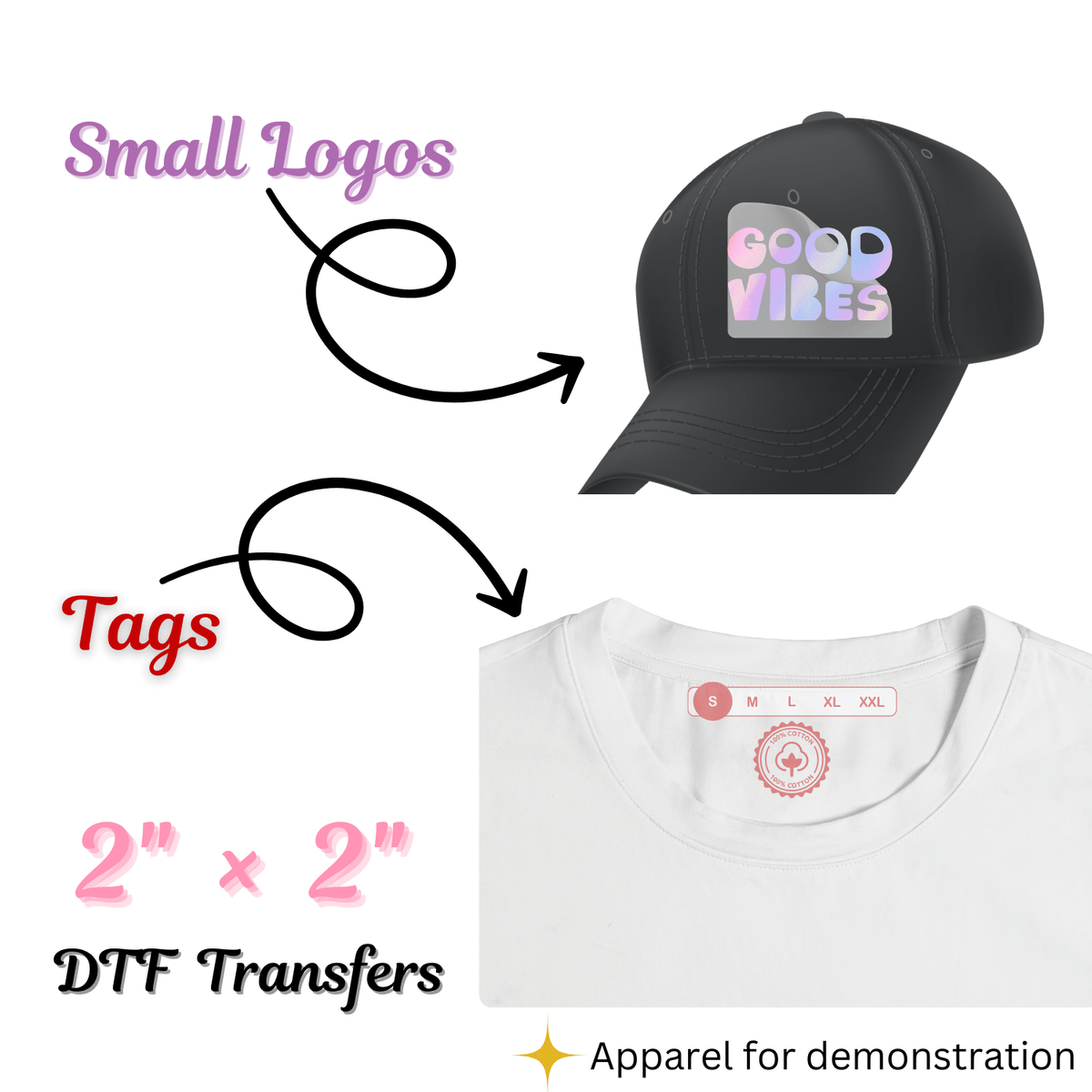

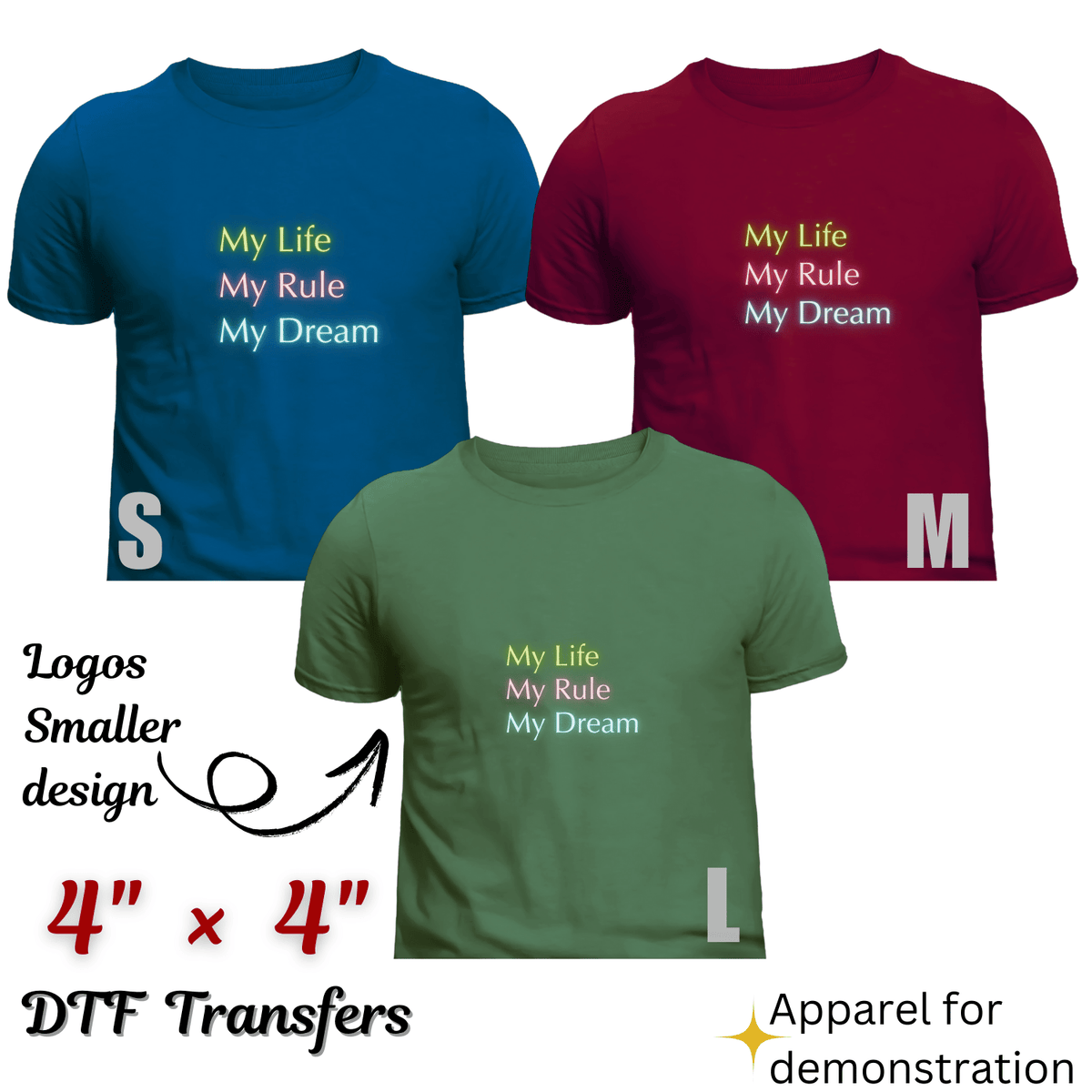

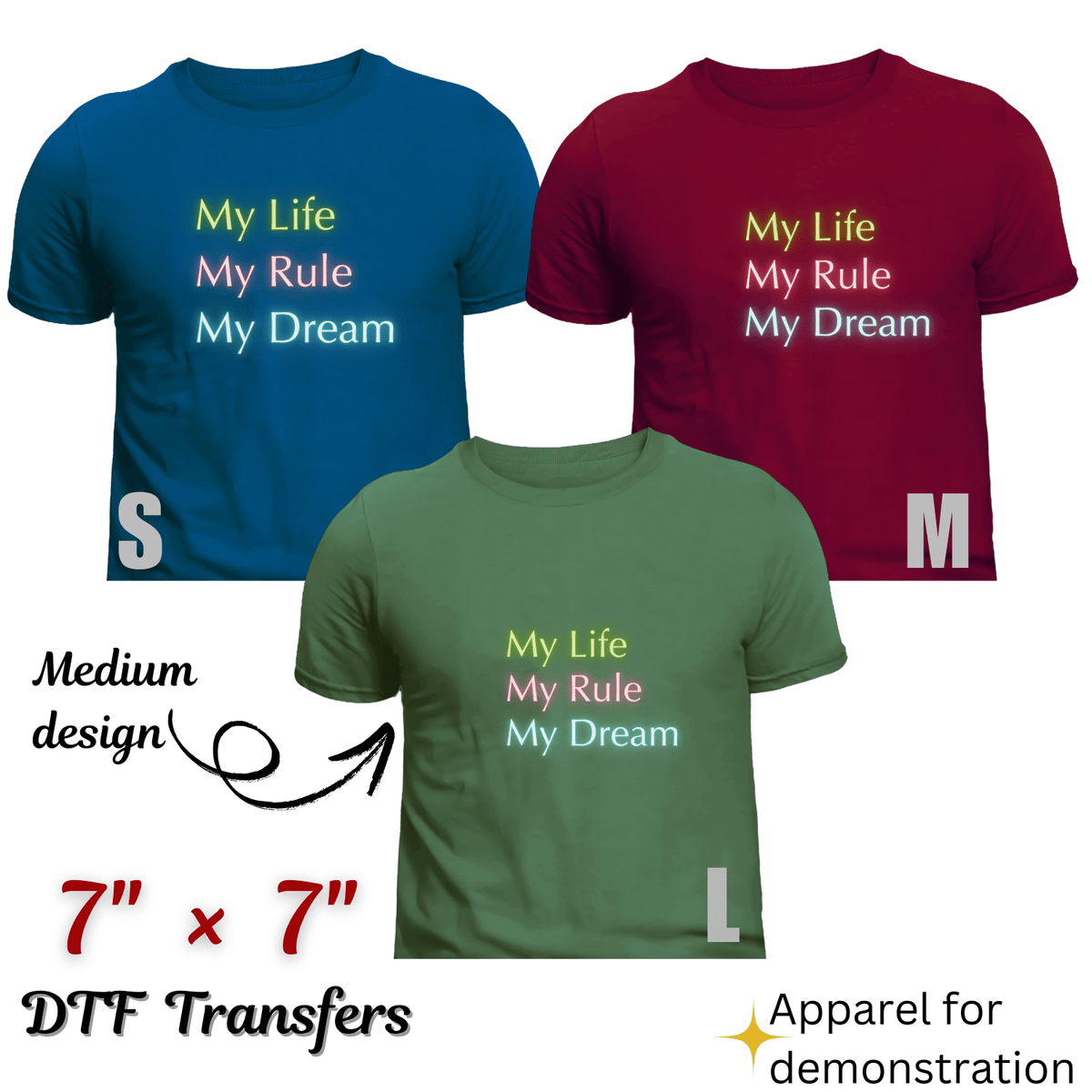

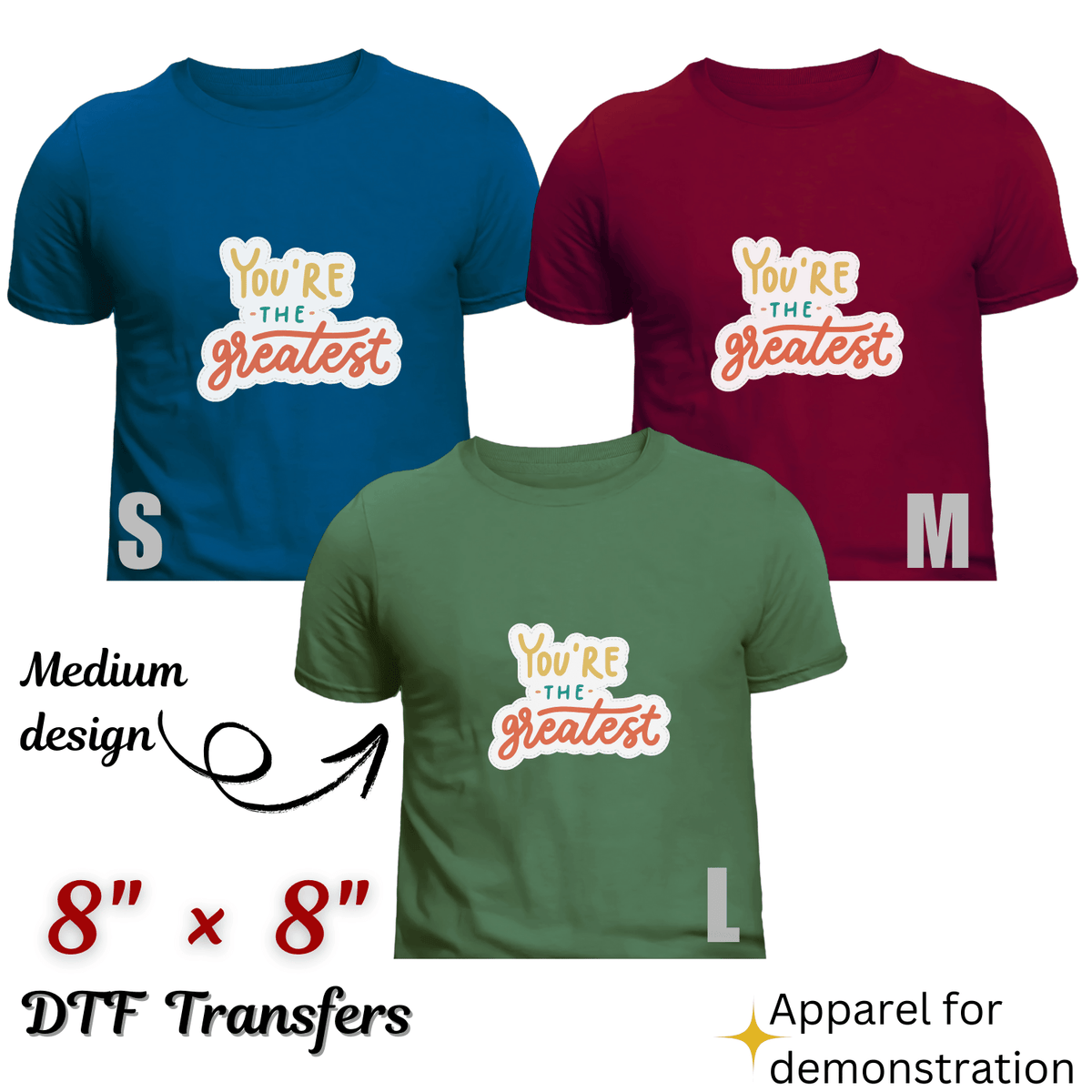

Custom DTF Transfers by Size

$0.64

- 2" width

- 3" width

- 4" width

- 5" width

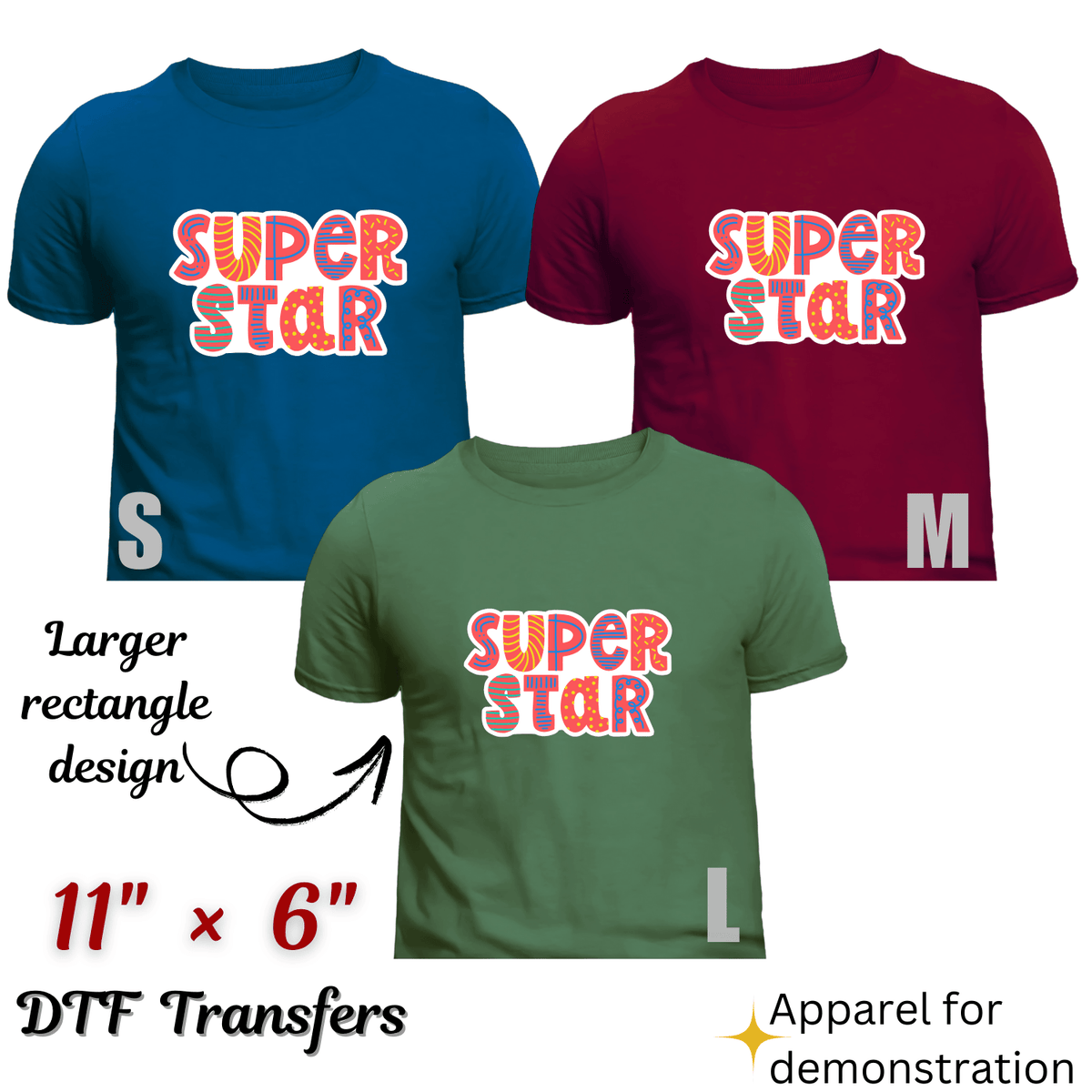

- 6" width

- 7" width

- 8" width

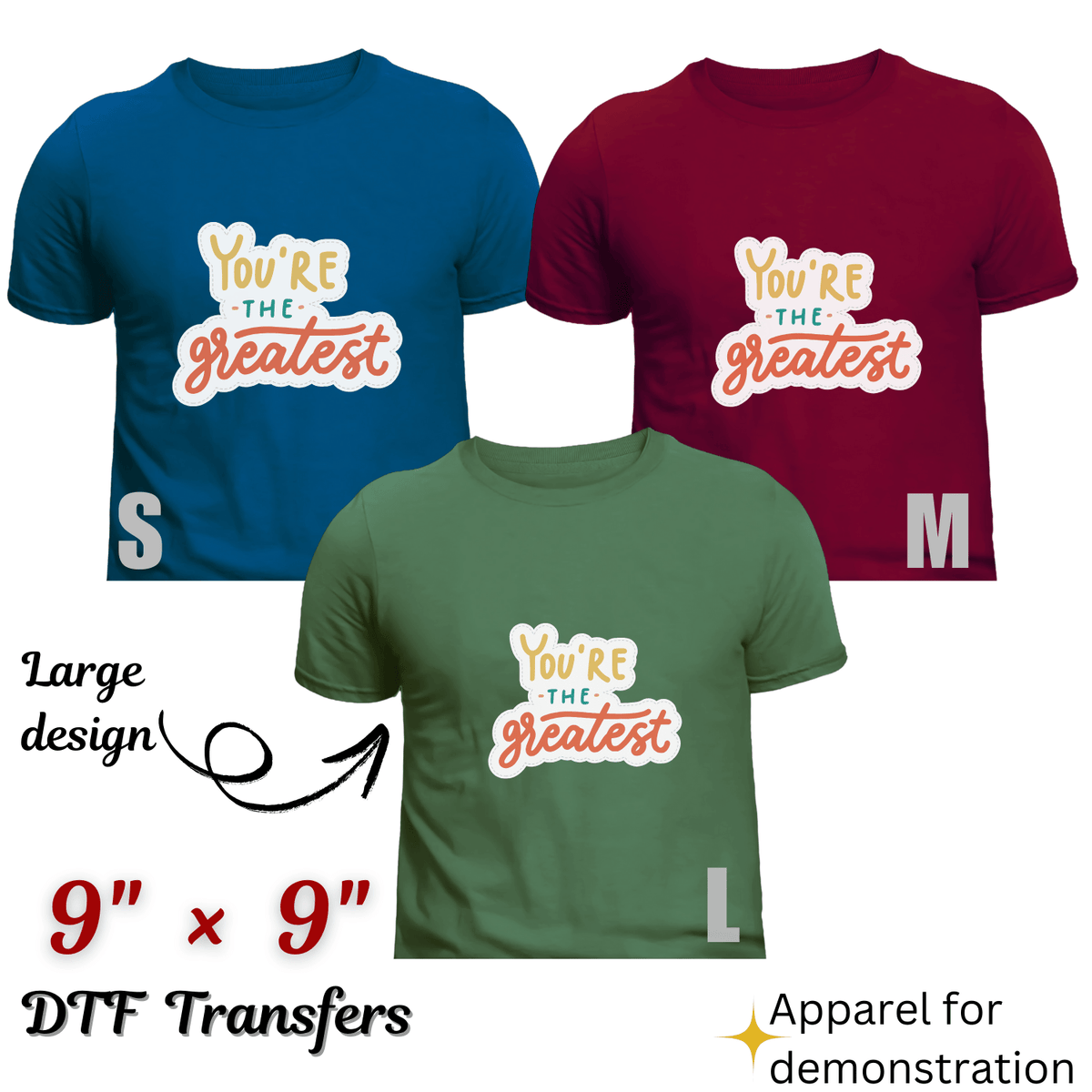

- 9" width

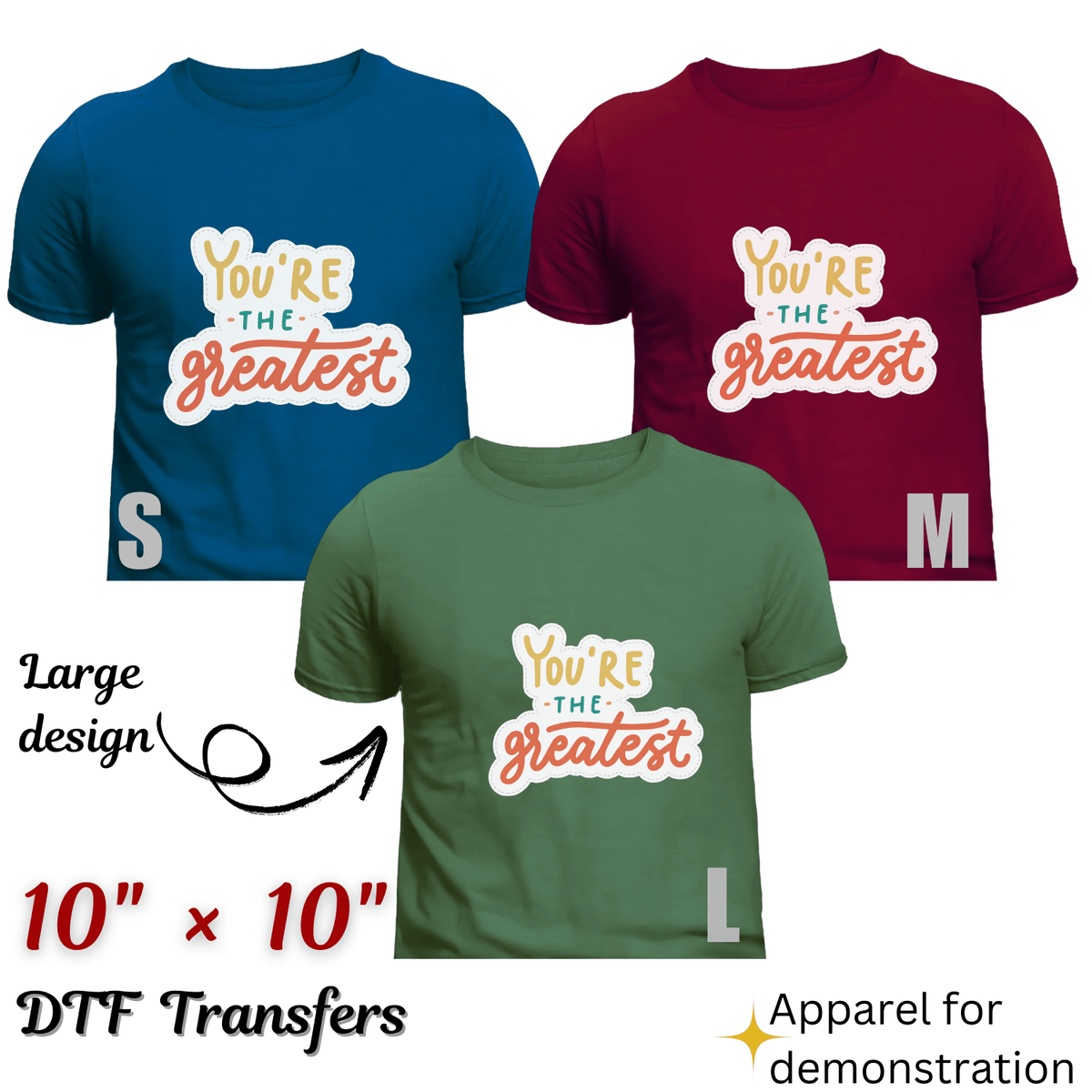

- 10" width

- 10.5" width

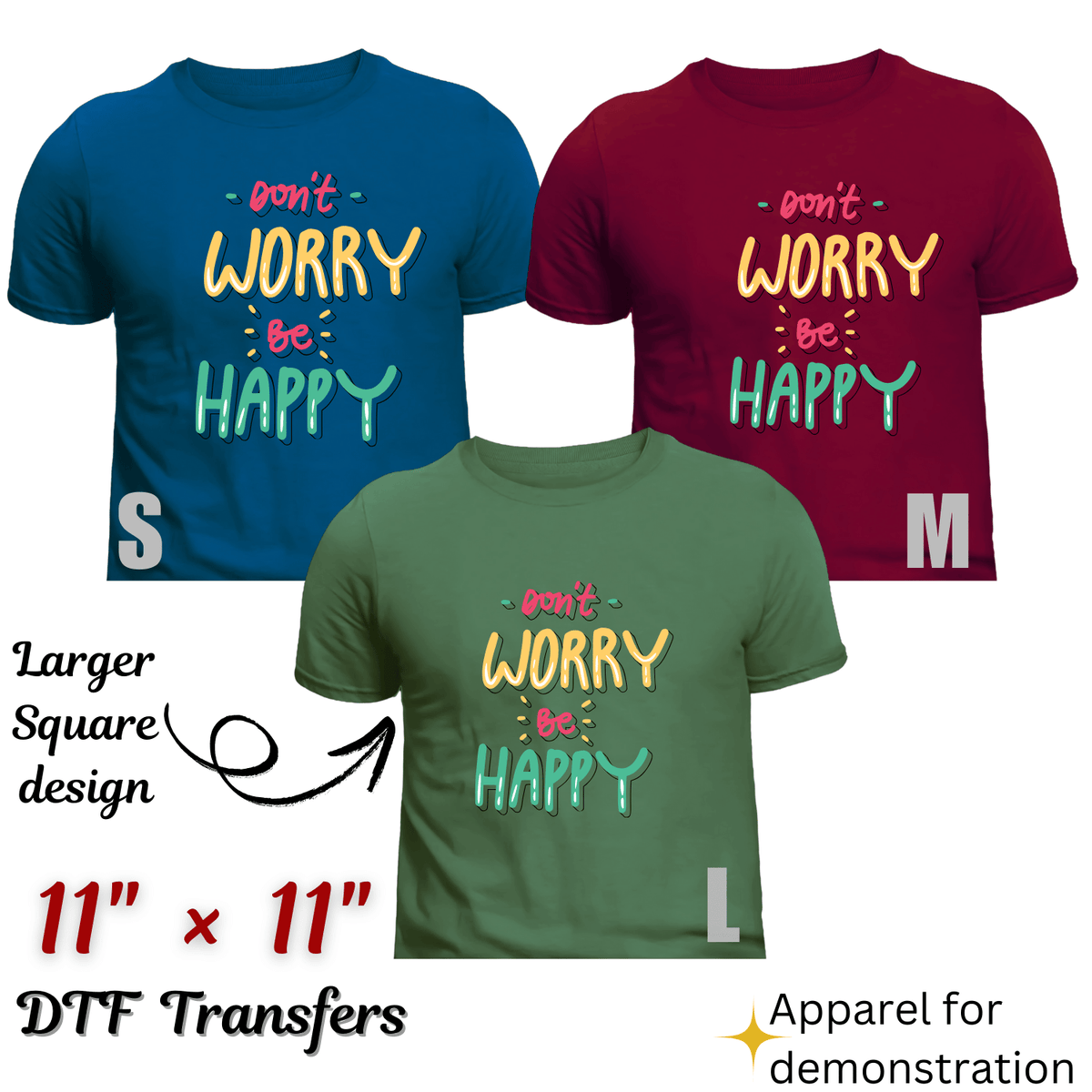

- 11" width

- 11.5" width

- 12" width

- 12.5" width

- 13" width

- 14" width

- 15" width

- 16" width

- 17" width

- 18" width

Product Description

DTF Instructions

Heat Press Settings:

- Temperature: Preheat to 300-310°F (155C)

- Pressure: Medium to high pressure (6 KG)

- Time: Press for 13 seconds

- Cooling: Allow 15 seconds to cool before peeling (can be cold or hot peel)

Important Note: Please check steps for printing for more details.

Ensure your print-ready files are uploaded before 8 AM CST for same-day processing!

Print Freedom: Unlock Your Creativity with DTF Gang Sheets

Discover the limitless potential of our DTF Gang Sheets, crafted for the visionary entrepreneur. These sheets transform the printing experience, allowing you to efficiently produce multiple designs in one go without sacrificing quality.

Versatile Applications: Easily print your designs onto apparel, accessories, and more, opening doors to a variety of custom products that reflect your unique brand.

Precision Printing for Unmatched Results

Experience professional-grade prints with our DTF Gang Sheets. Each detail of your design is meticulously captured, from intricate patterns to bold graphics, ensuring your creations make a memorable impact.

Whether you're an industry veteran or just starting out, our DTF Gang Sheets are engineered to meet the highest quality standards. Elevate your brand with prints that truly represent your dedication to excellence.

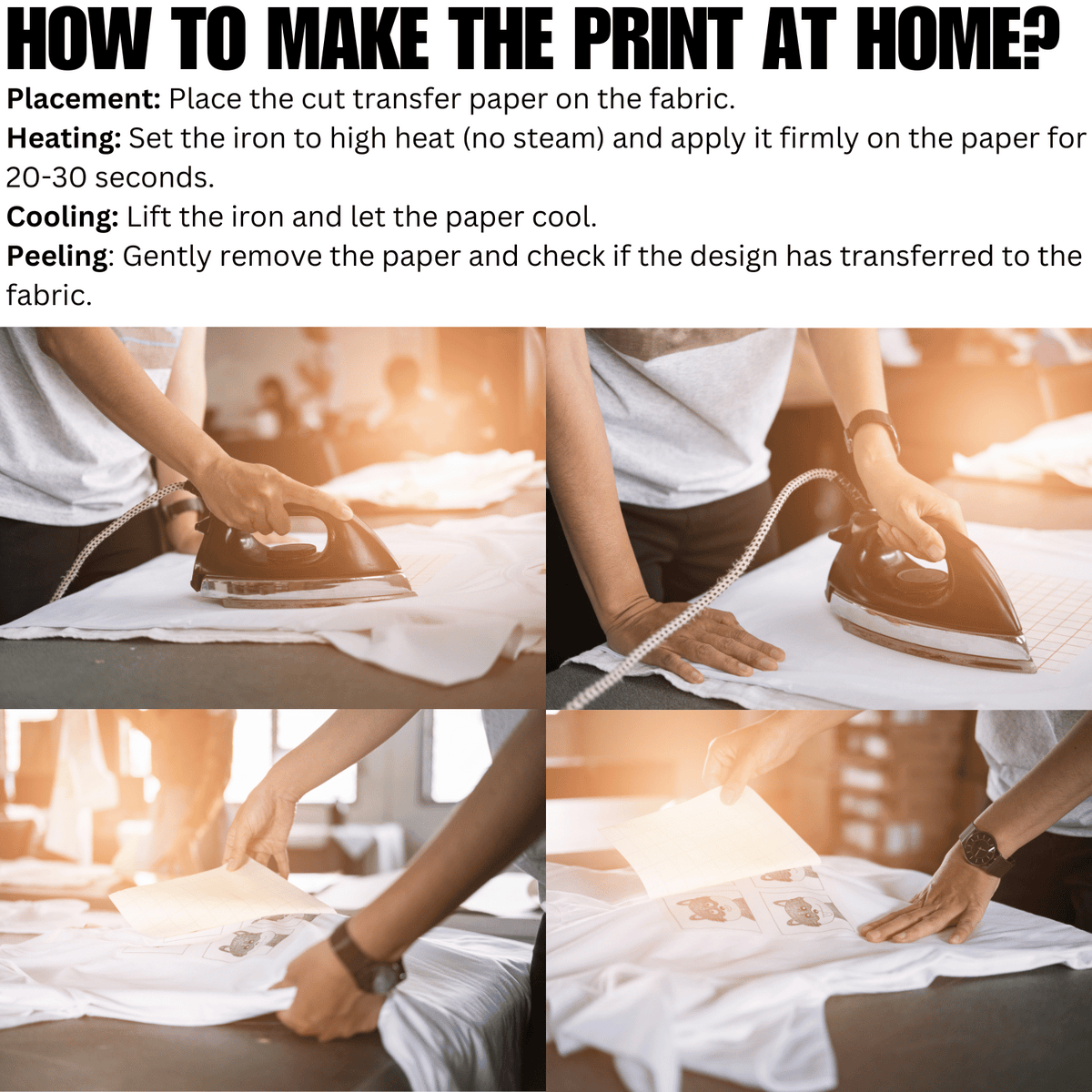

Steps for printing DTF transfers

Pressing Instructions:

- Press at 310°F / 155°C for 13 seconds with medium to high pressure using a dry iron (no steam).

- To avoid direct contact with the garment, use parchment paper or a protective guard sheet.

- Applying extra heat, pressure, or time won’t damage the transfer but may scorch the garment. If scorching occurs, reduce the pressure first; if needed, lower the temperature by 10-15°F while keeping the reduced pressure.

Peeling Process:

- Let the transfer cool for 15-30 seconds before peeling.

- Peel slowly, monitoring to ensure all parts of the design adhere properly.

- If any part doesn’t stick, reapply the transfer, increasing the pressure and heat by +15°F. If necessary, increase the temperature in 15°F increments until successful adhesion.

Final Press for Finish:

- After peeling, cover the design with parchment paper or a single layer of t-shirt fabric and press for another 15 seconds.

- This step improves durability and softens the design, also reducing shine. If a glossy finish is desired, use a guard sheet instead for the final press.

Washing Instructions:

- For longevity, wash the garment inside out in cold water. Dry on low heat or hang to dry.

- Standard wash settings are fine, but delicate settings further extend the design’s life.